Scanners

DOF Bench Scanner

- In extraoral scanning, conventional impression is performed and the resulting impression or model in plaster is scanned with a bench scanner.

- This method does not eliminate the clinical steps of obtaining the mold and / or model, which implies a longer time for making the prosthetic work.

- However, it becomes more practical for the laboratories since the works will be developed digitally via CAD / CAM.

- This method is more accurate in digitization since the light beam (image capture) remains static, while the model is moved over a fixed distance, thus avoiding image distortion.

- The digitalization of the image is obtained by an optical impression specific to each company, which uses technology to digitize the images in 3D and has software compatible with that image to carry out the digital drawing.

- The quality of the generated image must be considered, as there needs to be compatibility with the software and the milling machine, so that the full digital flow can be established.

- Currently, these systems allow the preparation of the prosthetic structure from the 3D visualization of the preparation image, the emergency profile, the occlusion, the assembly in a digital articulator and the color selection.

DOF Facial Scanner

- It is a small device that, combined with a tablet or PC, allows you to quickly scan the patient’s face and obtain all the face data in 3D with high precision.

- The Facial Scanner Snap allows you to scan a patient’s face and illustrate it in 3D instantly.

- With more accurate data, prosthetic devices can be manufactured with more accuracy, with better definition of the midline and smile line.

CAD-CAM

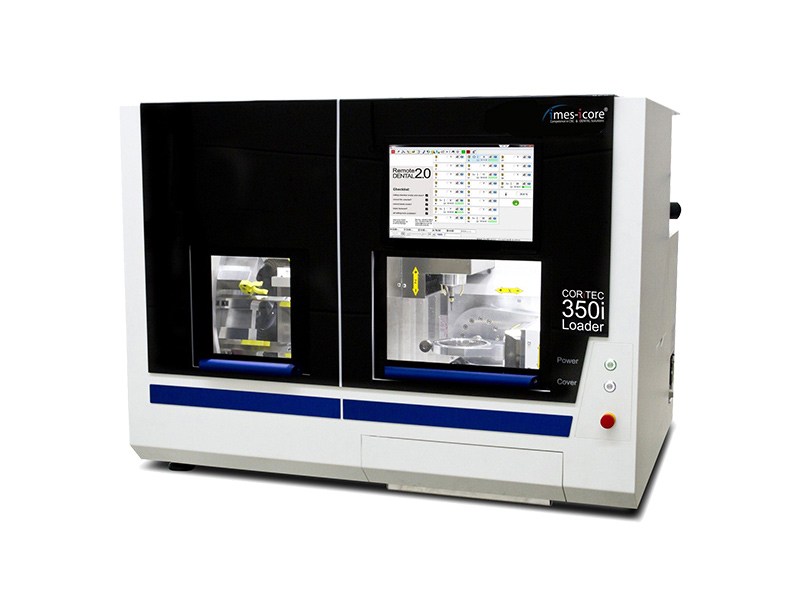

Labside – imes-icore – 350i Loader Pro Milling Machine

- High definition dynamic servomotors with absolute measurement systems on the 5 axes that increase processing speed by up to 20%, while maintaining optimum accuracy.

- An additional advantage of the Pro series is that this machine system is built from a unique structure made of polymer concrete and, as such, guarantees greater stability for milling without vibration.

- This model has a compact design and is suitable for a large volume laboratory or milling center.

- This model has a fully automated blank compartment that allows versatile milling of up to 12 blanks in unmanned operation.

- Due to the precise repositioning of the zero point fixing system, different prefabricated column supports can be adapted. Integrated computer with touch screen.

3D Printing

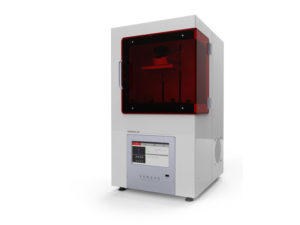

Microlay Versus Printer

- 385nm FullHD UV LED Light with Internal Radiometer. To maintain the best print quality, it is necessary to provide exactly the same amount of UV energy in each layer.

- Changes in energy may cause irregularities and surface artifacts. In addition, a few hours after use, LEDs tend to lose intensity, requiring constant adjustments to material profiles.

- Thanks to its internal radiometer, this model is able to automatically calibrate the amount of energy not only before each impression, but also before each layer in less than a second, ensuring accuracy in the same impression and also over the years (service life up to 50,000 hours).

- The solid state light engine and DLP FullHD projector (1920 x 1080px), allow this 3D printer to print with a resolution of 65 microns in the horizontal XY plane and 50 microns in the vertical Z plane (up to 10 microns).

- The degree of detail, reliability and surface finish are very interesting.

- The 385nm UV light source ensures compatibility with most premium resins available on the market, including white and transparent resins that are problematic with other printers with visible light projectors.

- Temperature control by heating the printing chamber, using hot air by convection, managing to create the ideal microclimate for each resin, thus reducing its viscosity and facilitating repeatability.

XYZ Printing – Solidifying

- The Solidificadora produces focused and consistent UV lights at 360 ° to solidify prints made with photopolymerizable resins.

- The post-curing process increases the hardness and durability of printed products.

- The camera has a 360 ° turntable and an internal reflective mirror with a maximum size of Ø180 x H200mm.

Unlike other UV chambers that use mercury lamps, the XYZ Printing UV Curing Chamber uses UV LED diodes.

- The light source does not produce ozone, which is much more environmentally friendly and energy saving.

The lamp life can last up to 10,000 hours, ensuring the curing of prints for a long time.

Ceramic Ovens

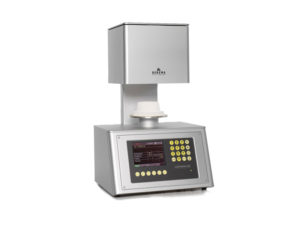

Dekema AUSTROMAT D4 Oven

- With a 32-bit electronic system and a display with two lines or a polychromatic screen, this equipment remains a benchmark for reliability and longevity.

- The improved sensor system for monitoring the parameters ensures exceptionally constant cooking results.

Dekema AUSTROMAT 674 Oven

- Suitable for sintering zirconia prostheses of any size, at a maximum temperature of 1530°C.

- The SiC concept for milled zirconia structures of all sizes up to forty units per level, allows the possibility of stacking on two levels. It has three heating elements that guarantee a uniform temperature in the cooking chamber.

Ivoclar Vivadent Programat EP 3010 Oven

- Ceramic oven with a new fully automated injection function (FPF), which allows injecting IPS e.max Press restorations.

- The user only has to place the coating cylinder in the injection furnace and press the start button. The oven selects the program, automatically heats the injection chamber to the correct temperature and injects the fluid ceramic into the coating cylinder at the appropriate time.

- The improvement in injection results increases when the FPF technique is used in combination with the new coating material IPS PressVest Premium.

Microscope

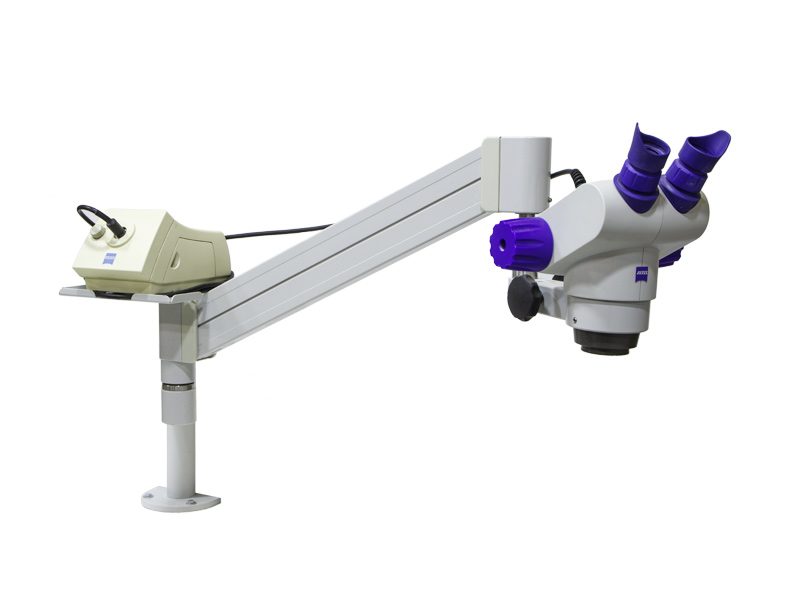

Zeiss MOD. 305 SPOT – Binocular Microscope

- The use of the microscope aims to identify small imperfections imperceptible to the naked eye during the process of making crowns, partial bridges and total structures.

- The laboratory has the possibility of correcting important details such as air bubbles in the ceramic cover or micro-fractures, as well as checking the perfect fit between the prosthetic elements made and the plaster models that represent the clinical situation in the oral cavity. .